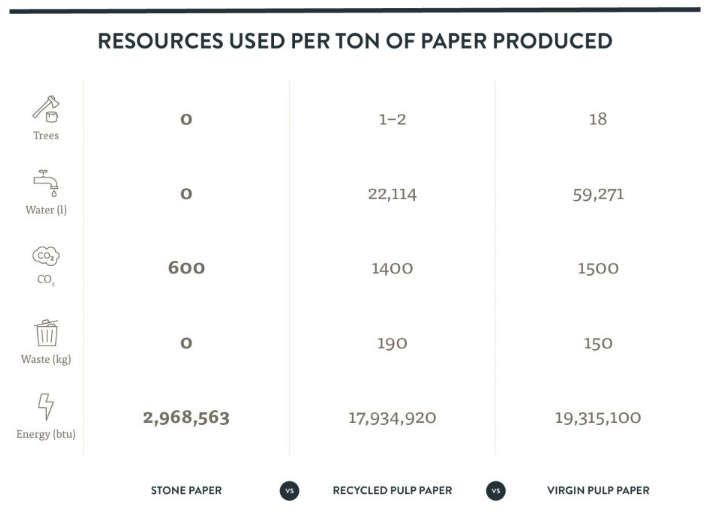

Stone paper vs. pulp paper – what’s the impact of stone paper?

In a previous blogpost, we explained the production process of stone paper. Now, we would like to show some figures regarding the exact resources saved when producing stone paper, in comparison to traditional pulp paper. Stone paper vs. pulp paper!

To make these numbers a bit more insightful:

- The water saved by producing stone paper instead of virgin pulp paper, is equivalent to taking a three-day long shower;

- The difference in CO2 emission is equivalent to driving around the world in a car driving 3.5 times;

- The energy saved with the production of one ton of stone, is the amount one average household uses over a two-month period.

As you can see, you save a lot of important resources when choosing stone paper over regular pulp paper. Even recycled pulp paper.